Basic technique for building assessment

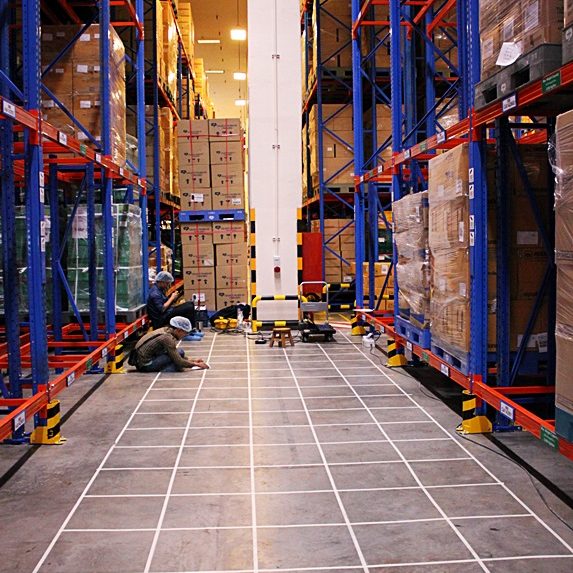

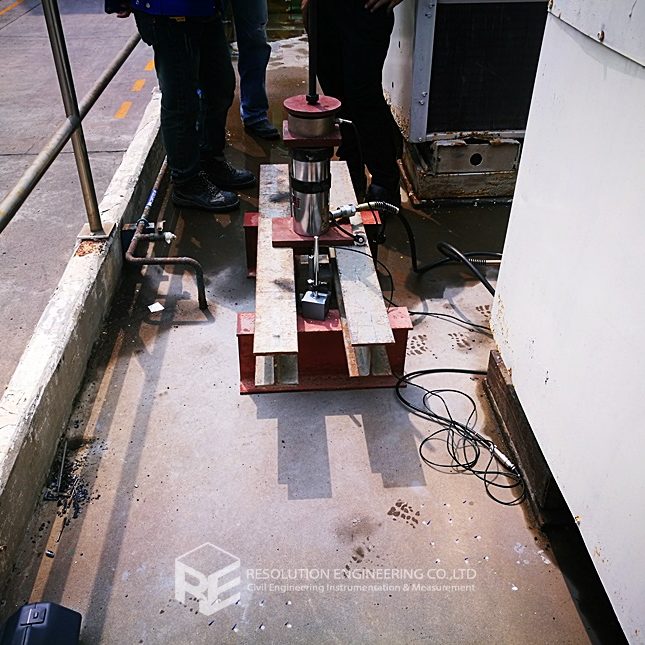

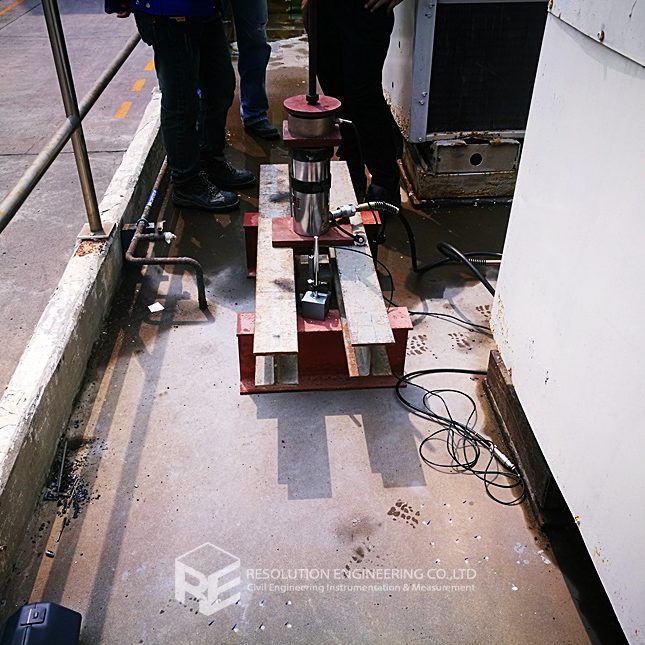

Visual inspections are generally conducted as the first step of structural evaluations due to its simplicity and benefit-to-cost advantage. The structural geometries, e.g. tilting, levelness, plumb, and settlement, will be carefully investigated using geometric surveying equipment (digital theodolite, measuring tapes, bubble level, etc.) to identify the possible major structural threats. The conditions of structural materials from the appearance (cracking, rusting, spalling, moisture, etc.) will be examined for material deterioration evaluations. The results from visual inspections will be further used in the planning of the more comprehensive structural evaluations if necessary.

Common physical damages found are.

- Construction defects such as porosity in concrete or damage on the concrete surface

- Cracking of concrete, of which the directions and the extent of such cracks can indicate the possible causes of the cracks and the level of damage

- Decomposition of concrete which can be caused by various factors, and the condition of which is commonly found in buildings which can easily affected by chemicals or salt water

- Structural distortion or movement

- Loss of concrete surface as a result of erosion

- Filter media failure

- Water seepage

- Concrete scaling

In the inspection process, detailed records of data and images of damages will be collected which will then be summarized in a report.

The structural visual inspection test can be conducted in conjunction with structural damage mapping in order to yield a clearer overview of the damage and the more accurate location of the damage, and in conjunction with the settlement survey for more accurate data on any distortion or disruption parts of the structures.